Project Description

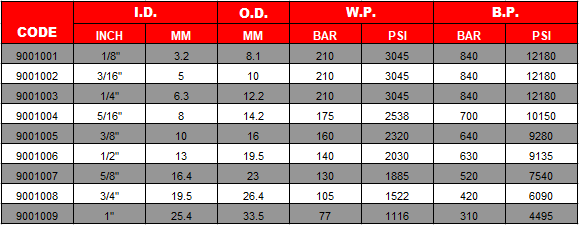

Blue Airless Spray Painting Hose 210Bar

Working Temperature:

-40°C to +100°C

Airless paint spray hose systems for 200 to 325 bar. Suitable for applications requiring chemical resistance to solvents and aggressive fluids due to low permeation value of polyamide, the hose is also suitable for industrial gases.

Applications:

High pressure painting

High pressure hydraulics

High pressure solvent, paint, chemicals

High pressure water-jetting

Core: Polyamide

Reinforcement: Single steel wire braid

Cover: Blue colour Polyurethane and optional pin pricked. Available Twin & Multi lines with different hose combination and size.

-40°C to + 100°C Temp not to exceed

+70°C for Air and water based fluids.

Other sizes & lengths are available on request.

1.BLUE AIRLESS SPRAY PAINTING HOSE EXCEEDS SAE 100R7

Application: Airless paint spray systems for 228 to 360 bar. Suitable for applications requiring chemical resistance to solvents and aggressive fluids. Specially suitable for pulsating electric piston pumps

Temperature Range: For solvents,paints,hydraulic fluids -40’C to +93’C

Fittings: BSP or NPS

Inner Tube: Polyamide

Reinforcement: two layers of braided high resistance synthetic fiber

Cover: Pin pricked anti-abrasion polyurethane

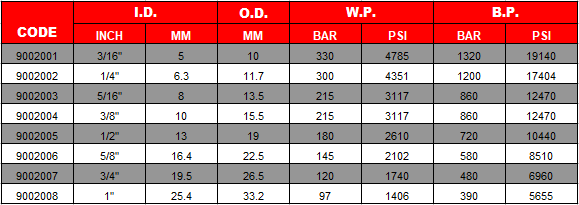

2.BLUE AIRLESS SPRAY PAINTING HOSE

Application: Airless paint spray systems for 100 to 350 bar. Suitable for applications requiring chemical resistance to solvents and aggressive fluids. Due to low permeation value of polyamide, the hose is also suitable for industrial gases

Temperature Range: For solvents,paints,hydraulic fluids -40’C to +93’C

Fittings: BSP or NPS

Inner Tube: Polyamide

Reinforcement: Single braid of steel wire

Cover: Polyurethane, Blue Colour, Pin pricking (Optional)

* For more information of JYM products, please contact us. If you would like a quotation or further information, please fill in the form below and we will reply to you within 1 working day.

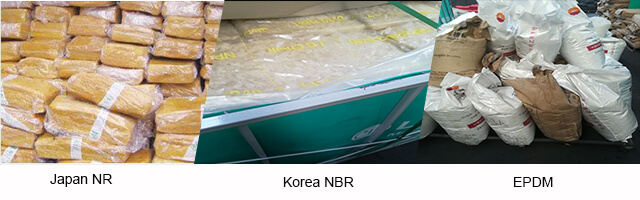

Material

Most of our rubber material imported from foreign countries( South Korea LG, Malaysia) Some bought from domestic market such as Sinopec China.

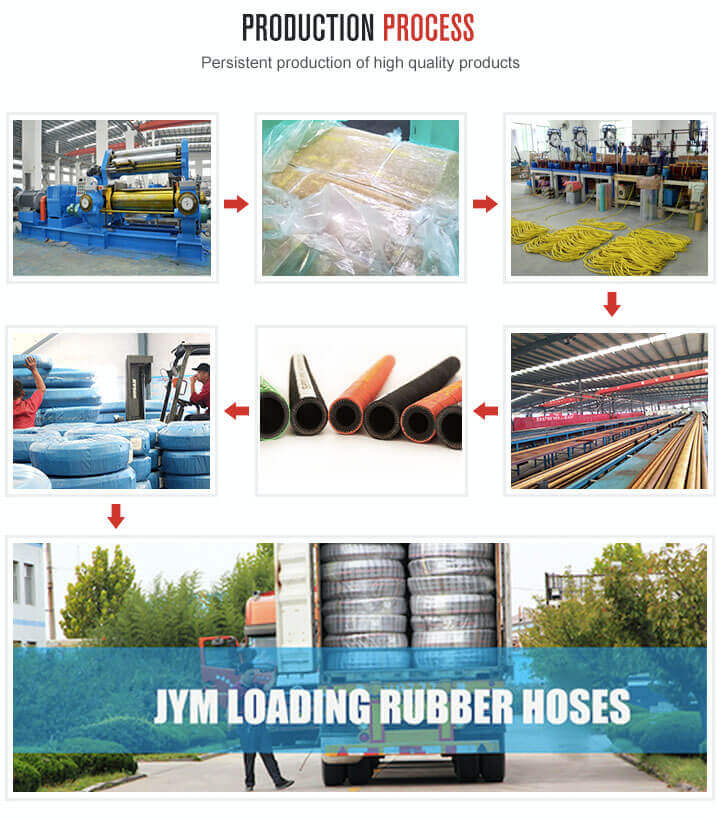

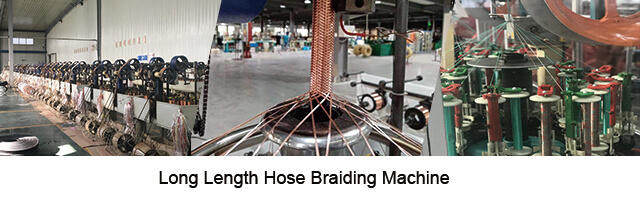

Production Process

Our Rigid Mandrel built production line can manufacture 60M length hoses.

Equipment

Advanced Italy VP production lines

R&D Center

Our factory has strong quality control team, we set up advanced laboratory before the mass production, we test each batch of raw material. After the production, we test each hose to guarantee a 100% qualification. Each hose tested 2 times of working pressure before packing.

Warehouse