Getting yourself a quality air compressor hose is essential to ensure stable air pressure, a tight seal and a consistent power output, but with a huge range of variety of hoses available on the market, it can be difficult to know where to start when making your selection. Whether you’re a home or professional air compressor user, you’ll need a dependable air hose to get the most out of your air tools.

We’ve pulled together our years of experience to deliver the ultimate, how-to buy an air hose guide. We’ll take you through all the decisions you’ll need to make before you invest in your new pneumatic equipment.

WHEN SHOULD YOU REPLACE YOUR AIR HOSE?

There are two reasons you’d want to upgrade your air hose. The first is you want to upgrade your air system so you can use different tools, or you’re looking to get more out of your system. The second is that there’s a defect in your existing air hose and you need replace it.

CHOOSING THE PERFECT AIR HOSE FOR YOU

With numerous varieties of air hose available to buy, sifting through all the choices and information can seem daunting. In reality, these really only four things you need to decide before you start your shopping:

- How long a hose do you need?

- What should the internal diameter of the hose be?

- What material should your hose be made from?

- Do you want a standard or recoil hose?

We’ll go through each of the considerations in turn so you can make an informed decision before you part with your cash.

WHAT LENGTH AIR HOSE DO I NEED?

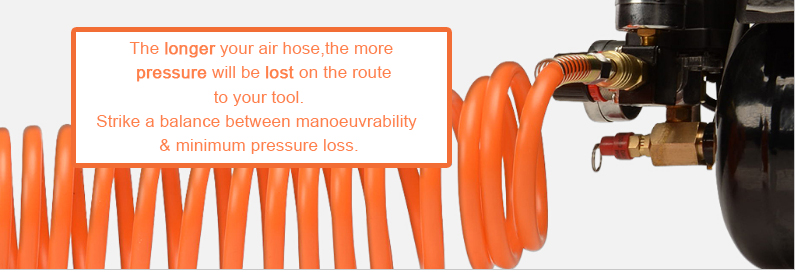

The length of your hose will directly affect the usability and performance of your air tools. You could purchase a single 50 metre hose and reach everything you could even want to reach – but we’d advise against it! Heaviness and bulkiness aside, the longer the hose from your compressor to your tool, the more air/pressure will be lost on route.

Think about what you’ll be doing with your air tool and how much movement you need to be able to do. For example, if you want to spray paint a car in a large workshop shop, you’ll need a lot more hose to navigate around, than say, someone who’s going to be using an air drill to make wooden toys on a work bench.

The aim when choosing an air hose length is to strike a balance between maximum manoeuvrability with your air tool and a minimum loss of pressure.

JYM standard air hoses are sold with couplers and connectors installed on them, meaning you can connect one hose to the other. You can extend your hoses reach almost indefinitely this way, however for each extra coupler you add, you may notice a small pressure drop.

WHAT DIAMETER AIR HOSE DO I NEED?

We measure air hoses by their internal diameter (or I.D). Simply speaking, the larger the hose I.D, the more air it’ll be able to carry. While the external diameter of air hoses will vary wildly depending on the quality of the hose and the material it’s made from, common internal sizes of air hose are 6mm, 8mm and 10mm internal diameter.

The rule of thumb when picking your hose I.D is the higher the CFM requirement of your air tool, the larger the diameter hose you’ll need. Hand held tools such as spray guns and nailers tend to require 1-3 CFM and will work perfectly well with a 6mm hose. A heavy duty impact wrench is more likely to require 6 CFM+, so you’ll probably require an 8mm or 10mm hose to run at full capacity.

The diameter of a hose will affect the overall weight of the line quite dramatically. Adding a couple of extra millimetres to the hose I.D. soon adds up over a distance. For small handheld tools, where dexterity counts, choose a 6mm hose.

SHOULD I CHOOSE A STANDARD HOSE OR A RECOIL HOSE?

The second is a recoil hose that has lots of small, regular twists, similar to traditional telephone wires. The coils are tensile and have a memory, so when you let go of the hose, it shrinks back for easy storage.

Choosing between the two is a matter of preference and individual application. For example, many factories use recoil hoses so they’ll spring out of the way when not in use. Many spray painters prefer a standard hose because they don’t like the resistance in a coiled line.

CHOOSING THE RIGHT FITTINGS AND CONNECTORS

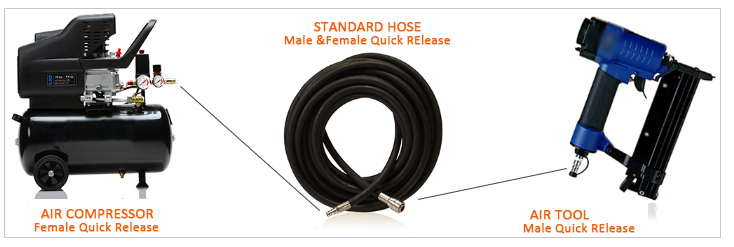

Most air hoses will come already fitted with some type of end fitting so you can start connecting up to your air compressor and tools.

This standard set up will allow you to attach your hose into most standard air systems. You’ll also be able link up your hoses to extend your reach. See the diagrams above for a typical set up for an air hose.

Having durable and reliable fixings is incredibly important for efficient and safe air tool usage, regardless of whether you’re a trade or home user. All JYM air fitting are fully CE rated and have been manufactured to the most stringent of quality standards.