How to ensure industrial rubber hose quality when JYM win an OEM order ?

An interview with Mr.Tony Chi,“Engineering consultant in JYM Industrial Rubber Hose.

Mr.Tony Chi has been in the engineering field for more than 14 year. He first began his formal

Engineering education at the university of Qingdao Science and technology in China.

His experience has led to hid involvement with industries such as pipeline, oil & gas transmission and petrochemical complexes.

Hose interaction

Breaking down his role in the industry, Chi stated that different disciplines plat their respective roles to ensure quality production. These include: Subject Matter experts, Quality and Inspection leaders, Supply Chain management, Quality Audit teams, and Contract and Procurement supervisors.

A subject Matter expert has the following key responsibility:

1. Specification Owner: Align, update, apply, management of changes and reword specifications

2. Consultant: Support to projects toward specifications, guidance toward technical management and trouble-shooting on operation

3.Field Engineer: Trouble shooting at site

Engineers are usually expected to find a solutions to everyday problem ,“You cannot wait for somebody to show you how it’s down on the site. If the problem requires you to get your hands dirty, then your must do that,” Tony Chi said. Although, when necessary , in cases when a new field engineer cannot find the solution themselves, team work with operations and guidance is provides. To fix the problem, as a colleague, one has to work in teams to review, discuss, understand and solve the problem that can help guide them to the right answers,’’he added.

When it comes to hoses specification, Tony Chi explained that they are used in various industries and applications, and specified date coming from end user sits, as well as contractors, and professional engineering firms. He said , “This date must be presented to ensure proper installation use of the hose materials regardless of construction and/of materials. Any information not presented to completely capture the intended application, may result in premature failure”.

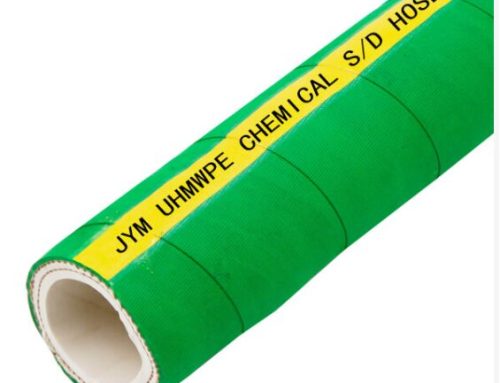

While discussing the different kinds of hoses used for different applications. Tony Chi said,’’ Hose and coupling manufactures/assembles hose styles which consist of Flexible Metal Hoses, Industrial Rubber Hoses,and PTEE or comparable thermoplastic constructions. ALL hoses are specified based on specific application date. We use the acronym STAMPED to determine the proper hose, and its suitability for the intended application. ’’ The acronym stand for :

-Size (generally nominal pipe size)

-Temperature (Upper and lower limits including design on upset condition)

-Application(External conditions such as abrasion , bending, climate, potential for crushing , kinking flexing, as well as possible exposure to chemicals, oils, ozone, and UV )

-Media (Type and concentration of the media being conveyed, and its compatibility with the hose )

-Pressure (Upper and lower limits including design on upset condition)

-Ends (Style, Type, and connection method, Pressure ratings of each, and the compatibility with the media)

-Delivery (Specific testing, tagging, packaging, and shipment methods)

“ Whenever applications of critical nature are presented, only hoses that are pressure tested and certified, i.e.CSA registered, are generally used”, Tony Chi said . He further added,” Manufacturers of such critical service hoses should normally produce at least two hoses of the same design and type, such that one is tested up to the highest design parameters for it to burst during testing. This proves the performance toward its design. This ‘burst’ test is recommended by end users because of the critical nature of the application. For example, if so gas leaks from a hose that is employed to transport it, it could be potentially life threatening to a person mere 20 feet away. When the second hose is installed, it proves that all the factors have been considered and limitations are tested to ensure safety in critical applications.’”

As we further delved into the type of projects that he works with, he said that he has worked on engineering assessments, and management of change projects. This requires not only supporting and evaluating vendors but getting involved in the complete process, i.e., from writing the date sheet, to supporting the procurement and being on-call during the time, and monitoring delivery after inspection.

A typical work day

In his vast and varied experience, Tony Chi has worked as a Subject Matter Expert for piping material, detailing specification involving valves and other associate equipment throughout is career. One of the primary duties include collection of subject matter equipment like flange, fitting, elbow, expansion joints and hoses, among others.

A typical work day for Tony Chi include 50% of his time being dedicated to new project, 25% in codes and regulations, and 25% in maintenance and reliability support, he engages in the review of documents submitted by vendors to make sure that currant industry practices are being implemented and to determine if the manufacturing expectations are met or exceed the company’s expectation.

Tony Chi’s daily interaction with hoses is plenty and very specific. As the industry expectation ia that the manufacturer will comply to not industry and corporate standards, he is responsible for the verification of those document, ultimately providing compliance to the project requirements.

Educating and mentoring

Tony Chi is a big believer in mentoring. He has coached and groomed many junior throughout his career, more than 200. “I always say that I am like a USB, you can download as much as ypu want,” he said with a laugh. He said ,“A student needs t be continuously pushed to their best ability to keep learning . They are encouraged to learn from their mistakes, and only then can they reach a point where they can deliver the right product.”

Tony Chi is not only firm believer in continuous learning and sharing knowledge, but also advocates the need to find the right path to oneself. As a mentor, the one piece of advise he always offers to young industry personnel is to search out and seek their own field of interest. He is a big believer in the need to identify whats makes somebody “and ”learn what they are capable of”.