Project Description

Floating Marine fuel hose

Characteristics:

1. Independent foam floating casing to prevent water absorption.

2. Outer layer with excellent resistance to abrasion, UV, aging

and corrosive environment.

3. Easy installtion and less maintenance

4. Customized steel flanges are available.

Floating Marine fuel hose

Construction:

Application:

These floating hoses are designed for the transportation of crude oil and liquid petroleum products between loading and unloading vessels at offshore moorings systems.

Standards and Specifications:

Floating oil and marine hoses are designed and produced in full accordance to OCIMF standards. These porducts are also subjected to manufacturing and testing requirements dictated by ISO9000:2001 quality standards.

Rated Working Pressure:

The flaoting hoses will have an RWP of not less than 15bar, 19bar and 21bar hoses are also available if specified by the customer. They are suitable for operation at an internal pressure from minus. 0.85bar to the RWP.

Flow Velocity:

The lining of the floating oil hose is made using an elastomer and fabric suitable for continuous operation at a flow velocity of 21m/s.

Resistance to Temperature, Oil products and Aging

The floating oil hose is suitable for crude oil and liquid petroleum products from-20℃ to +82℃,and an aromatic hydrocarbon content not greater than 50% by volume.

Electrical Continuity:

For electrically continuous hose, a low resistance connection will be provided by the copper wire and helix steel wire.

Insturction:

1. NBR compound synthetic rubber hose

2. Reinforcement: high tensile strength fabrics with helix steel wire

3. Independent foam

4. Cover: CR synthetic rubber

5. Ideal working temperature:-25℃ to +82℃

6. Safety factor:5:1

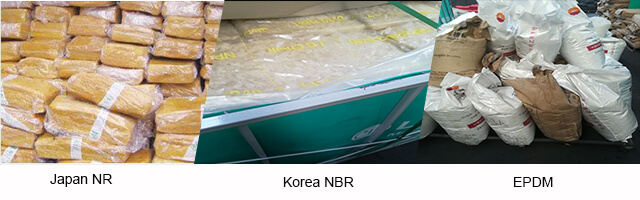

Material

Most of our rubber material imported from foreign countries( South Korea LG, Malaysia) Some bought from domestic market such as Sinopec China.

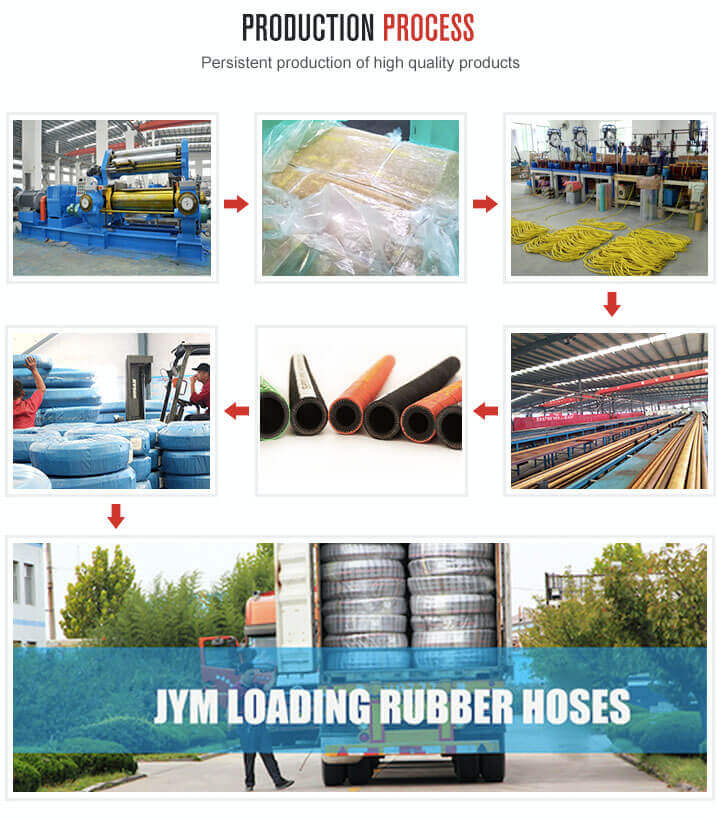

Production Process

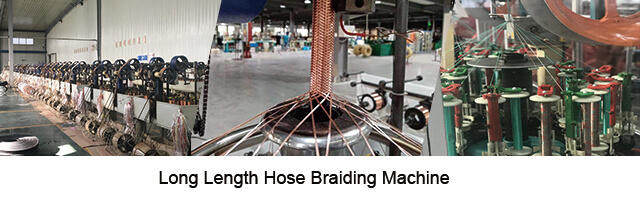

Our Rigid Mandrel built production line can manufacture 60M length hoses.

Equipment

Advanced Italy VP production lines

R&D Center

Our factory has strong quality control team, we set up advanced laboratory before the mass production, we test each batch of raw material. After the production, we test each hose to guarantee a 100% qualification. Each hose tested 2 times of working pressure before packing.

Warehouse

For any inquiry of JYM Hose, please kindly let us know. Our sales staffs will reply you as soon as possible in 24 hours.