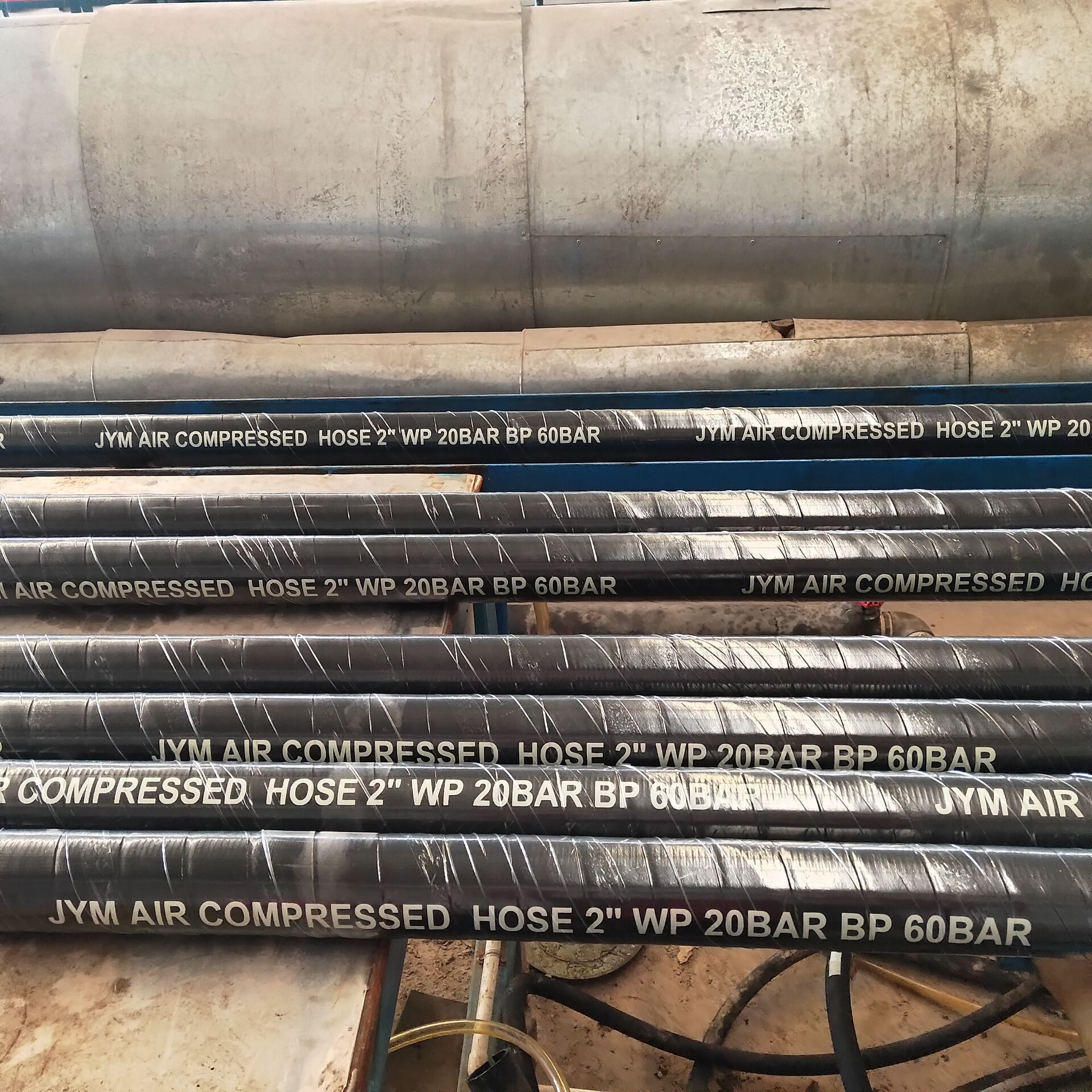

Air Compressed Hose: Technical Specifications and Applications**

Air compressed hoses, commonly referred to as pneumatic hoses, are essential components in various industrial and commercial applications. These hoses are designed to transport compressed air efficiently and safely, serving as the backbone of pneumatic systems. In this article, we will delve into the technical specifications and diverse applications of air compressed hoses.

Technical Specifications

1. Material Composition:

Air compressed hoses are typically made from durable materials such as polyurethane, PVC (polyvinyl chloride), or rubber. Each material has unique properties that cater to specific applications. For example, polyurethane hoses are lightweight and flexible, making them ideal for applications requiring high mobility, while rubber hoses offer superior abrasion resistance and durability.

2. Pressure Rating:

The pressure rating of air compressed hoses is a critical specification. Most hoses are designed to handle pressures ranging from 100 PSI (pounds per square inch) to 300 PSI, depending on the material and construction. It is essential to select a hose with a pressure rating suitable for the intended application to prevent rupture and ensure safety.

3. Diameter:

The inner diameter of the hose can vary significantly, typically ranging from 1/4 inch to 1 inch. The diameter affects the flow rate of compressed air; larger diameters can deliver higher volumes of air, while smaller diameters are suitable for more precise applications.

4. Temperature Resistance:

Air compressed hoses must withstand varying temperatures, ranging from -40°F (-40°C) to 158°F (70°C), depending on the material. It is crucial to choose a hose that maintains its integrity under the operating temperature conditions of your specific application.

5. Reinforcement:

Many air compressed hoses are reinforced with materials such as polyester or nylon to enhance their strength and flexibility. Reinforcement is particularly important for high-pressure applications, where the risk of hose failure is greater.

Applications

Air compressed hoses are utilized across a range of industries, including:

1. Manufacturing:

In manufacturing settings, air compressed hoses are used to power pneumatic tools, such as drills, wrenches, and paint sprayers. Their ability to deliver a consistent flow of compressed air makes them indispensable in assembly lines and production facilities.

2. Construction:

Construction sites rely heavily on air compressed hoses to operate various tools and machinery. From nail guns to air compressors, these hoses provide the necessary air supply to enhance productivity and efficiency.

3. Automotive:

In the automotive industry, air compressed hoses are used for tire inflation, paint spraying, and powering pneumatic lifting equipment. Their versatility and reliability make them a preferred choice for workshops and garages.

4. Agriculture:

Air compressed hoses are also employed in agricultural equipment for tasks such as powering irrigation systems and operating pneumatic seeders. Their durability and resistance to wear make them suitable for outdoor applications.

5.HVAC Systems:

In heating, ventilation, and air conditioning (HVAC) systems, air compressed hoses are used to facilitate air flow and control systems. They play a vital role in maintaining optimal conditions in residential and commercial buildings.

Conclusion

Air compressed hoses are critical components in numerous applications, providing efficient and reliable delivery of compressed air. Understanding their technical specifications—such as material composition, pressure rating, diameter, temperature resistance, and reinforcement—can aid in selecting the right hose for your needs. As industries continue to evolve, the demand for high-quality air compressed hoses will remain integral to operational success.