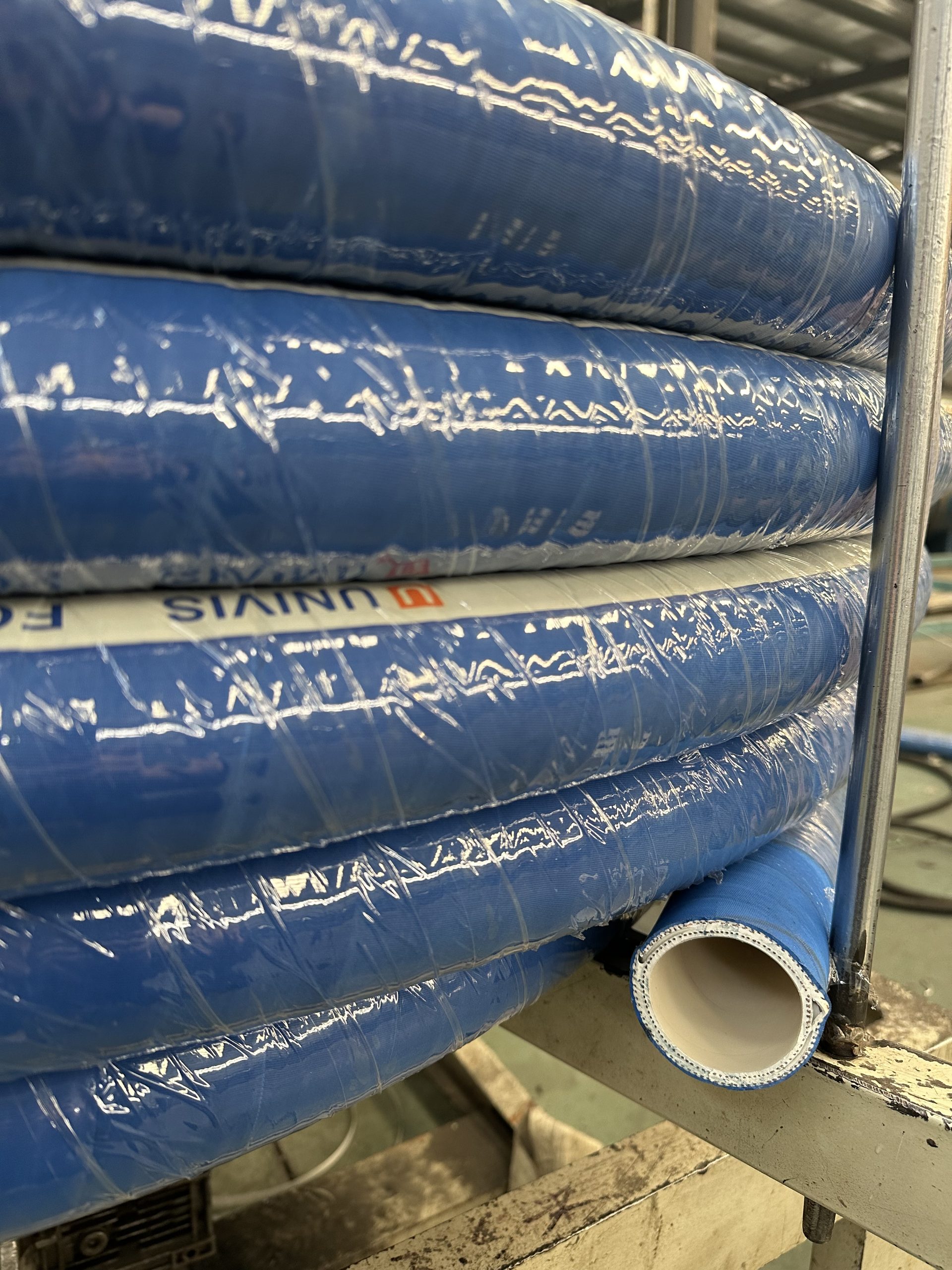

Food SD Hose: Technical Specifications and Applications

The Food SD Hose is a specialized product designed for the safe and efficient transfer of food and beverage products. This hose is engineered to meet stringent sanitary standards, ensuring that it is suitable for various applications in the food processing and distribution industries. Below, we delve into the technical specifications and applications of the Food SD Hose.

Technical Specifications

1. Material Composition:

– The Food SD Hose is typically constructed from high-quality, food-grade materials such as FDA-approved PVC or silicone. This ensures that the hose is free from harmful chemicals and contaminants, making it safe for food contact.

2. Diameter and Length:

– Available in various diameters ranging from 1 inch to 4 inches, the Food SD Hose can accommodate different flow rates and application requirements. Standard lengths usually range from 50 feet to 100 feet, but custom lengths can be manufactured upon request.

3. Temperature Resistance:

– The hose is designed to withstand a wide temperature range, typically from -40°F to 212°F (-40°C to 100°C). This makes it suitable for both hot and cold food products.

4. Pressure Ratings:

– The Food SD Hose is capable of handling pressures up to 150 PSI, making it ideal for high-pressure applications in food processing systems.

5. Reinforcement:

– The hose features a multi-layer construction with textile or steel wire reinforcement, providing excellent flexibility and durability while preventing kinking or bursting under pressure.

6. Surface Finish:

– The inner surface is smooth to minimize the risk of bacterial growth and facilitate easy cleaning. The exterior is designed to be abrasion-resistant, ensuring longevity in demanding environments.

7. Compliance and Certifications:

– The Food SD Hose complies with various industry standards, including FDA, USDA, and NSF certifications, ensuring it meets the safety requirements for food handling.

Applications

The Food SD Hose is versatile and can be used in a variety of applications within the food and beverage industry, including:

– Food Processing: Ideal for transferring liquid ingredients, such as oils, syrups, and juices, during processing stages.

– Brewery and Beverage Production**: Used for transferring beer, soda, and other beverages, maintaining the integrity and flavor of the products.

– Dairy Industry: Suitable for conveying milk and dairy products, ensuring hygiene and safety during transport.

– Food Packaging: Employed in packaging lines where food products are transferred to packaging machines.

– Sanitary Applications: Perfect for use in environments that require high levels of sanitation, such as food preparation areas and processing facilities.

In conclusion, the Food SD Hose is a reliable choice for food and beverage transfer, combining high-quality materials with robust technical specifications. Its versatility across various applications makes it an essential component in the food industry, ensuring safe and efficient operations.