Tank Truck Hose: Technical Specifications and Applications

Tank truck hoses are essential components in the transportation of liquids, particularly in the petroleum, chemical, and food industries. Designed to withstand harsh conditions and facilitate safe and efficient transfer, these hoses are engineered with precision to meet the diverse needs of various applications. This article delves into the technical specifications and applications of tank truck hoses, highlighting their importance in modern logistics.

Technical Specifications

1. Material Composition:

– Inner Liner: Typically made from rubber, PVC, or thermoplastic elastomers, the inner liner is crucial for compatibility with the transported liquid. For example, hoses for petroleum products often use Nitrile rubber due to its resistance to oil and fuel.

– Reinforcement: Multi-layered construction with textile or steel wire reinforcement provides flexibility and strength, allowing the hose to withstand high pressures and external impacts.

– Outer Cover: The outer layer is designed to resist abrasion, weathering, and chemical exposure. Common materials include rubber compounds or polyurethane.

2. Pressure and Temperature Ratings:

– Tank truck hoses are rated for various pressure levels, typically ranging from 150 psi to 300 psi, depending on the application.

– Temperature ratings can vary widely, with some hoses capable of handling temperatures from -40°F to +200°F (-40°C to +93°C), making them suitable for both cold and hot liquids.

3. Diameter and Length:

– Hoses come in various diameters, usually ranging from 1 inch to 6 inches, allowing for flexibility in transfer rates and volume.

– Standard lengths are typically between 20 to 100 feet, with custom lengths available to meet specific customer requirements.

4. Couplings and Fittings:

– Hoses are often equipped with cam-lock, threaded, or flanged fittings, ensuring secure connections that prevent leaks during operation. The choice of coupling depends on the specific application and regulatory requirements.

5. Compliance and Certification:

– Many tank truck hoses comply with industry standards such as API, ASTM, and FDA regulations, especially for food-grade applications. Certification ensures that the hoses meet safety and performance criteria.

Applications

Tank truck hoses are utilized across various industries due to their versatility and durability. Some common applications include:

1. Petroleum and Fuel Transfer:

– Used for transporting gasoline, diesel, and other petroleum products, these hoses are designed to handle the specific chemical properties of fuels while ensuring safety during transfer.

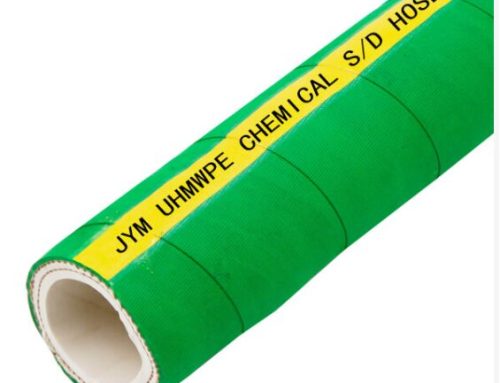

2. Chemical Transport:

– In the chemical industry, tank truck hoses are employed to move hazardous and non-hazardous liquids. Their resistance to chemicals and high-pressure ratings make them ideal for this application.

3. Food and Beverage Industry:

– Food-grade tank truck hoses are critical for the safe transfer of liquids like milk, juices, and other consumables. These hoses are designed to meet stringent hygiene and safety standards to prevent contamination.

4. Water and Wastewater Management:

– These hoses are also used in municipal and industrial water transfer applications, as well as in the management of wastewater, where durability and resistance to various substances are essential.

5. Agricultural Applications:

– Tank truck hoses are utilized in the agriculture sector for the transportation of fertilizers, pesticides, and other liquid products, ensuring efficient delivery to the fields.

In conclusion, tank truck hoses are vital for the safe and efficient transport of liquids across various industries. Their technical specifications, including material composition, pressure and temperature ratings, and compliance with industry standards, make them a reliable choice for logistics operations. As industries continue to evolve, the demand for high-quality tank truck hoses will remain paramount in ensuring safety and efficiency in liquid transportation.