UHMWPE Chemical Suction and Discharge Hose: Technical Applications and Specifications

Introduction

Ultra-High Molecular Weight Polyethylene (UHMWPE) chemical suction and discharge hoses are specialized hoses designed for transporting a wide range of chemicals and hazardous materials. Their unique properties make them an ideal choice for industries such as chemical processing, pharmaceuticals, food and beverage, and oil and gas. This article delves into the technical applications and specifications of UHMWPE chemical hoses, highlighting their benefits and versatility.

Technical Applications

1. Chemical Resistance

UHMWPE hoses exhibit outstanding chemical resistance, allowing them to handle a variety of aggressive substances, including acids, alkalis, and solvents. This property makes them suitable for transporting:

– Acids: Sulfuric acid, hydrochloric acid, and nitric acid.

– Solvents: Acetone, ethanol, and toluene.

– Alkalis: Sodium hydroxide and potassium hydroxide.

These hoses are engineered to withstand the corrosive effects of these chemicals, ensuring the safety and integrity of the transported materials.

2. Food and Beverage Applications

In addition to chemical resistance, UHMWPE hoses are approved for food-grade applications. They comply with FDA and European Food Safety Authority (EFSA) regulations, making them suitable for transporting edible oils, juices, and other food products. Their non-toxic and odorless properties ensure that the quality of the transported substances remains uncompromised.

3. Oil and Gas Industry

The oil and gas sector often requires hoses that can handle hydrocarbons and other petroleum products. UHMWPE hoses are designed to withstand high pressures and temperatures, making them ideal for suction and discharge applications in this industry. Their flexibility and durability also allow for easy maneuverability during operations.

4. Pharmaceutical Applications

In pharmaceutical manufacturing, the purity of materials is paramount. UHMWPE hoses are designed to prevent contamination, ensuring that active pharmaceutical ingredients (APIs) are transported safely. Their smooth inner surface minimizes the risk of product buildup and facilitates easy cleaning.

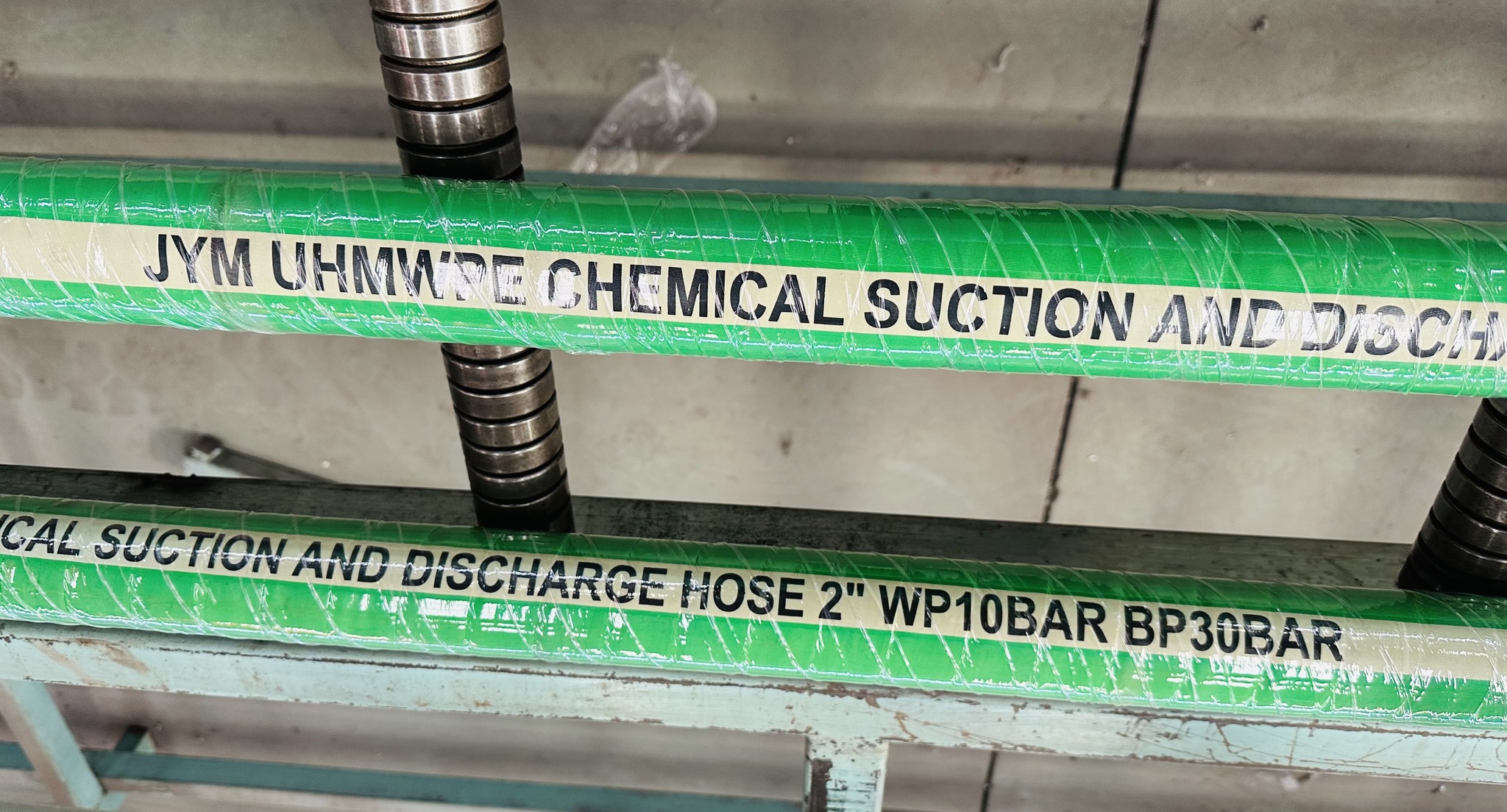

Technical Specifications 1. Material Composition

UHMWPE is known for its high molecular weight, which contributes to its superior abrasion resistance and impact strength. The hoses are typically reinforced with multiple layers of synthetic fabric and steel wire to enhance their structural integrity and pressure capabilities.

2. Temperature Range

UHMWPE hoses can typically operate within a temperature range of -40°F to 180°F (-40°C to 82°C). However, specific temperature ratings may vary depending on the hose construction and application, so it is essential to consult product specifications.

3. Pressure Ratings

The pressure ratings of UHMWPE chemical hoses can vary based on their diameter and construction. Standard pressure ratings range from 150 PSI to 300 PSI, making them suitable for various industrial applications. Always refer to manufacturer guidelines for specific pressure ratings.

4. Diameter and Length Options

UHMWPE hoses are available in various diameters, typically ranging from 1 inch to 8 inches. Custom lengths can also be manufactured to meet specific application requirements, ensuring flexibility in usage.

5. Fittings and Couplings

To ensure leak-proof connections, UHMWPE hoses can be fitted with a variety of couplings and fittings, including cam lock, flanged, and threaded options. The choice of fittings should align with the hose’s intended application to ensure optimal performance.

Conclusion

UHMWPE chemical suction and discharge hoses are an essential component in various industries requiring the safe and efficient transport of chemicals, food products, and pharmaceuticals. Their exceptional chemical resistance, durability, and compliance with safety standards make them a preferred choice among professionals. By understanding their technical applications and specifications, users can make informed decisions when selecting the right hose for their specific needs.