Project Description

Super Blast Sand Blasting Hose – 2-PLY & 4-PLY

Marking: Super Blast-19 19x33MM W.P. 12Bar B.P. 36Bar

Temperature:-35℃~+80℃

Tube: Smooth, black, antistatic, abrasion resistant NR/BR rubber compound.

Reinforcement: Textile, wrapped.

Cover: Black, antistatic, weather and abrasion resistant SBR/NBR rubber compound, cloth impression.

Abrasion loss value: Acc DIN 53516≤60mm³

The inside of the sandblasting hose is made of natural rubber, which has a considerable resistance to abrasion. The outer layer is made of a polymeric material. There is reinforcement, which acts as a double textile braid. From sandblasting to choose the right hose is directly dependent on the speed and quality of sandblasting and abrasive consumption.

Sandblasting Hose

- Blasting hose is designed for supply of abrasive materials and is used in jet engines and installations blast cleaning surfaces with structures serving quartz sand, steel shot, sliced, corundum, nikelshlaka, kupershlak etc;

- High life expectancy abrasion resistant inner layer. In the production of sandblast hose is used only high-abrasion rubber that allows to obtain high-quality sandblasting hose with a lifetime of about 3-5 times higher than that of many Chinese and Russian counterparts sandblasting hose;

Types:

- 1 braid sandblasting hose

- 2 ply sand blast hose

- 4 ply sandblast hose

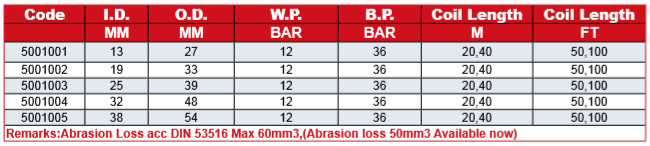

Sand Blast Hose 2-PlY (ISO3861:2008)

Application:Wear-resistant, electric conductive blasting hoses Suitable for any kind of abrasive blasting job. Hose inner tube is made of highest abrasion resistance natural rubber

Marking: Super Blast-19 19x33MM W.P. 12Bar B.P. 36Bar

Temperature:-35℃ ~+80℃

Tube:Smooth, black, antistatic, abrasion resistant NR/BR rubber compound. Abrasion according to DIN 53516:1987. Max. 60-70 mm3.

Reinforcement: Textile, wrapped.

Cover: Black, antistatic, weather and abrasion resistant SBR/NBR rubber compound, cloth impression.

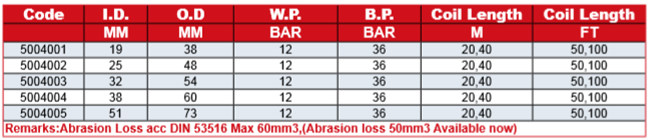

Sand Blast Hose 4-PlY (ISO3861:2008)

Abrasion Loos acc DIN 53516 Max 60mm3 (Abrasion loss 50mm3 available Now)

Tube: Natural Rubber Reinforcement:4-Ply textile

Cover:Wrapped Surface (Black,Green,Red) Operating Temperature: -40’C to +70’C

Application:

• Conveys sand or shot for cleaning purposes

• Conveys sand from sandblast equipment to clean steel or concrete before painting or sealing

Markets:

• Construction

• Metal working

• Ship building

What You Should Know About Sandblast Hose

The inside of the sandblasting hose is made of natural rubber, which has a considerable resistance to abrasion. The outer layer is made of a polymeric material. There is reinforcement, which acts as a double textile braid.

From sandblasting to choose the right hose is directly dependent on the speed and quality of sandblasting and abrasive consumption.

The standard length of the blast hose: – 20 and 40 meters.

The sleeve fits (steel shot, silica sand, glass, corundum, kupershlak, grenades and so forth. Can be used) for sandblasting

The sleeve fits (steel shot, silica sand, glass, corundum, kupershlak, grenades and so forth. Can be used) for sandblasting- Antistatic internal layer protects from the appearance of electrostatic discharge

- The inner layer is made of natural rubber with high resistance to abrasion

- Working pressure: 12 bar

- Burst pressure: 36 bar

- Sleeve working loads at different temperatures from -35 to +80 degrees

Wear abrasive blasting sleeve inside leads to the loss of pressure during transport of air-abrasive mixture, as a consequence of reduced cleaning rate and increased consumption of abrasive material. Therefore, the savings on sandblasting hose price may be questionable and lead to higher costs in the production of sandblasting work.

Sandblasting (abrasive) sleeve has a high resistance to abrasive particles. Used in systems and plants and sand blasting different surfaces and parts. With these sleeves, by means of compressed air supply is made of steel shot, quartz sand, corundum and other materials used for cleaning. Sandblasting sleeve widely used in the construction industry for supplying different solutions (cement, gypsum, etc.), as well as concrete mixtures using concrete pumps. Products at work do not accumulate static electricity, which ensures their safe use. The use of wear-resistant materials for the production of hoses for long life of their operation, and to enhance the strength of reinforcement is carried out using a tissue winding. All products meet international standards system DIN ISO 4649: 2006. Allowed to operate at temperatures from -35 o C to +80 o C.

With sand-blasting method can achieve varying degrees of purification. When cleaning, can be divided into metal surfaces purity 4 following groups:

1. Sandblasting effect reminiscent of cleaning with a wire brush.

Routine cleaning of surfaces without a mirror shine effect.

Clean metal surface almost to perfection.

2. Clean the surface of the metal to full brightness.

The choice of treatment should be determined in advance depending on which coating was applied to the metal surface: corrosion, enamel, primer, zinc or plastic coating, etc.

• Blasting hose is designed for supply of abrasive materials and is used in jet engines and installations blast cleaning surfaces with structures serving quartz sand, steel shot, sliced, corundum, nikelshlaka, kupershlak etc;

• very high life expectancy abrasion resistant inner layer. In the production of sandblasting hose is used only high-abrasion rubber that allows to obtain high-quality sandblasting hose with a lifetime of about 3-5 times higher than that of many Chinese and Russian counterparts sandblasting hose;

As practice shows, from how sandblasting sleeve is always directly dependent on the quality of the device is selected correctly, jet speed, abrasive consumption. It is very important to consider that this structural element is always exposed to increased wear and require particularly careful choice in quality and durability.

In order to determine the condition of the hose it is recommended to periodically use a special gauge. If the pressure in it is reduced at 1 atm., Recommended replacement. Quickly wear out the air hose does not allow the installation to fully operate. This leads to a loss of pressure reduction purification rate of volume increase sacrificial abrasive. As a result, savings in the cost of the hose leads to a significant increase in operating costs.

In order to determine the diameter of the blasting hose is sufficient to multiply the inner diameter of the nozzle at the 3. Select hose with a margin on the length are not recommended, as it will lead to the senseless loss of pressure.

Before starting work, always check the outlet pressure. If you have recorded a loss of pressure even by 1 bar compared with a new hose, replace it. Failure to replace the blast hose can rupture the hose, that is unsafe.

When purchasing a sandblasting hose, you have to understand that it is not necessary to save, because here it is necessary to use a hose with an inner diameter as large as possible. The pipeline for the air supply may not be large enough. The larger internal diameter of the blasting hose, the less friction loss.

In order to choose the right sandblasting sleeve, determine the diameter of a blast nozzle you want to use. For correct operation, the hose diameter should be 4 times higher. Buy sandblasting sleeve is only required length, unjustified increase in length will lead to pressure loss.

Generally, not all of the same sleeve sandblasting quality. Choosing a quality sleeve for sandblasting, you will provide a continuous speed, the quality of treatment and reduce the consumption of abrasive material transmitted through the hose.

Sandblasting hose is mainly used for the plating of the workpiece, between the different parts of the bonding before the processing, casting parts of the burr, cleaning, polishing to remove the surface of the workpiece stains, mechanical parts to increase the application of a wider, but spray Sand tube has its own unique characteristics, but in the product structure of sandblast hose and other hose structure the same, from the outer rubber cover, braided layer, the inner layer of glue composition. General outer layer of fine weather resistance, weaving layer sometimes use steel wire weaving, sometimes use textile cord, the inner glue is generally better wear resistance (determined by the transmission medium).

How to use sandblasting hoses?

Do not use more than the maximum temperature withstand pressure, according to the transmission medium, where the work environment to choose the appropriate wear sandblast hose.

Do not use more than the maximum temperature withstand pressure, according to the transmission medium, where the work environment to choose the appropriate wear sandblast hose.- The new sandblast hose in the pressure will appear the expansion and contraction, so the choice of hose length to stay when the margin.

- The pressure applied to the sandblasting rubber hose, to uniform pressure to prevent the phenomenon of burst pipe appears.

- In general use, try to avoid the hose bending less than its minimum bending radius.

- Metal hose coupling can be very good to avoid sandblasting high pressure hose joints wear.

- The continuity of the requirements of the wear-resistant sandblasting hose assembly, the need to regularly check the wear-resistant sandblasting tube electrostatic discharge and export situation, to avoid damage to the hose due to arc perforation.

- Do not put sandblasting hose near the open flame.

- The workers must wear protective equipment before work, Do not bare naked arm work. Working should not be less than two people

- Checking the loss of sandblasting hose regularly, if inner layer found loss seriously, the skeleton layer of hose appears, the outer layer of cracking and other phenomena, replace new sandblasting hose in time.

Proper use of sandblasting hose can extend the life cycle of the product, but also try to avoid accidents in the workplace.

From sandblasting to choose the right hose is directly dependent on the speed and quality of sandblasting and abrasive consumption.

We recommend that you select the sandblasting hose from a trusted manufacturer. Cheap sandblasting hose can be of questionable quality, and its service life can be 4-10 times lower than that of a good abrasive wear sleeves.

Life time

Wear abrasive blasting sleeve inside leads to the loss of pressure during transport of air-abrasive mixture, as a consequence of reduced cleaning rate and increased consumption of abrasive material. Therefore, the savings on sandblasting hose price may be questionable and lead to higher costs in the production of sandblasting works.

Periodically check the pressure loss in front of the nozzle using a special gauge needle. By reducing the pressure of 1 bar or more, compared with a new sleeve, it recommended replacement. Use a hose to the gusts of the state is unsafe and economically unfeasible.

How to choose the right rubber sandblast hose?

The diameter of the blasting / shot blasting hose should be 3-4 times larger than the internal diameter of the blasting nozzle. This will avoid loss of pressure, speed reduction blasting abrasive and cost overruns.

The diameter of the blasting / shot blasting hose should be 3-4 times larger than the internal diameter of the blasting nozzle. This will avoid loss of pressure, speed reduction blasting abrasive and cost overruns.

I do not recommend you to choose the blasting hose with a stock length. If the works are assumed in the vicinity of the sandblaster, it is best to choose a small sandblasting hose length (10-20 meters). The excessive length of the blast hose will lead to pressure loss and senseless unnecessary wear of the inner surface.

If the works are removed, it is necessary to choose the 40-meter or 60-meter blasting hose and try to avoid them as much as possible connections with each other, as this leads to a loss of pressure. In the case of the use of arms neobimosti over 60 meters must use safety cables in the ground connection hoses.

Do not buy the sandblasting hose with plenty of length, as abrasive blasting hose is too long will lead to the loss of pressure and a rapid deterioration of the sleeve material. If you have to work at a small distance from the blasting installation, it is enough hose 10-20 meters. If the work area greatly removed from the blast installation, you should choose a forty-meter hose. Interconnect two hose twenty meters is highly undesirable, since such a compound results in a pressure loss and deterioration in quality. The main enemy of performance sandblasting works – it is the joints in the sandblasting hose, high pressure.

- The inner diameter of the sleeve must be greater than the throughput capacity of the nozzle 3-4 times.

- Selecting the blast hose with a double or four-seal, it depends on the type of work performed.

- Cut the sleeves should be made exactly the right angle.

- To analyze the operating pressure of the device before the acquisition of the sleeve. It prohibited the use of sleeves in excess of allowable values.

- All hoses must be fitted with safety ropes from corrosion-resistant steel braiding and spring-loaded terminal to the coupling loops.

In practice, often used abrasive hoses with too small internal diameter. The main rule is that the inner diameter of the sleeve should be 3-4 times higher through put holes on sandblasting nozzle.

Sandblast hose for supply of air from the compressor to the sandblasting unit must have a sufficient inside diameter.

When purchasing a sandblasting hose, you have to understand that it is not necessary to save, because here it is necessary to use a hose with an inner diameter as large as possible. The pipeline for the air supply may not be large enough. The larger internal diameter of the blasting hose, the less friction loss.

The loss from the friction of only 0.1 atm sleeves system leads to capacity reduction of 2 per cent. The loss from the friction of 1 atm is already capacity reduction of 20 per cent.

Our sleeves are characterized by high strength. Used in their manufacture of high quality materials with the addition of special polymers that promotes slower wear products.

Sandblasting sleeve can be used in cleaning or grit blasting, and supply mortars. After the abrasive sleeve you can supply plaster, cement, plaster, as well as through concrete pump hoses.

At the core of our market strategy base on the principle of low prices for the goods and services of high quality. That’s what helps our partners always get their competitors.

Quality control of the goods produced by the party carried out the quality control group and begins at the delivery and acceptance of raw materials to the manufacturing plant.

Next is monitored all the production processes from the sampling and assessment of the quality in the laboratory.

After completion of the manufacturing process of the complete cycle that carried out a final check of the finished product packaging, as well as the quality of loading containers for further transport.

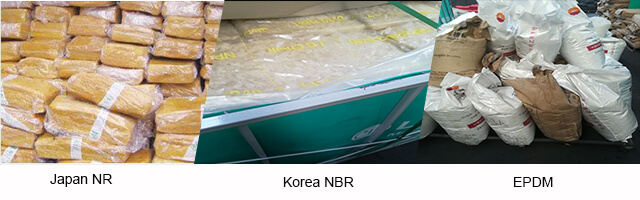

Material

Most of our rubber material imported from foreign countries( South Korea LG, Malaysia) Some bought from domestic market such as Sinopec China.

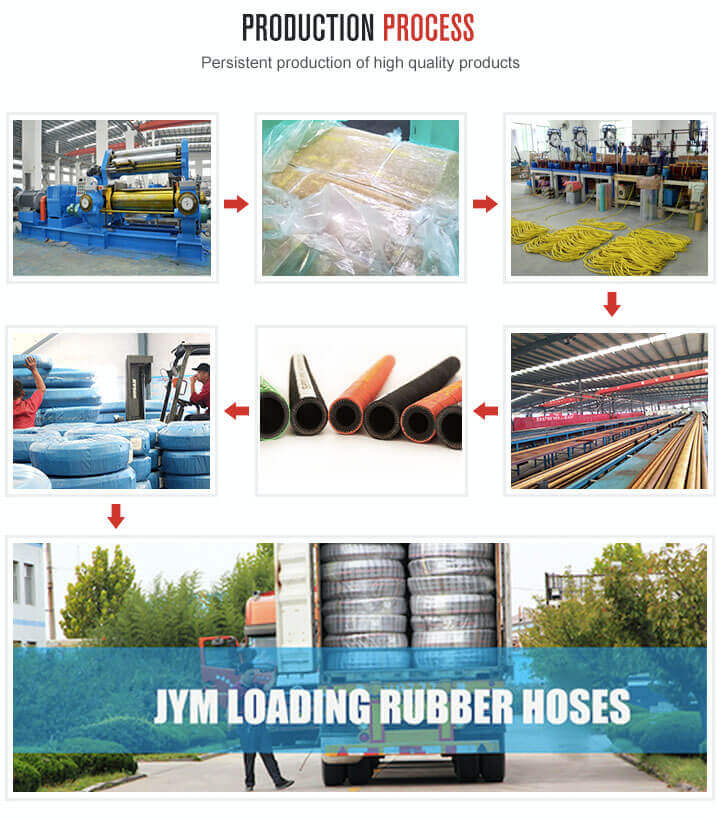

Production Process

Our Rigid Mandrel built production line can manufacture 60M length hoses.

Equipment

Advanced Italy VP production lines

R&D Center

Our factory has strong quality control team, we set up advanced laboratory before the mass production, we test each batch of raw material. After the production, we test each hose to guarantee a 100% qualification. Each hose tested 2 times of working pressure before packing.

Warehouse

* For more information of JYM products, please contact us. If you would like a quotation or further information, please fill in the form below and we will reply to you within 1 working day.