Rubber Oil Hose also called rubber fuel oil hose, flexible reinforced oil hose, oil hose pipe, reinforced fuel tubing, fuel oil pipe line. It is usually being made of at least inner layer (NBR synthetic rubber), reinforcement (high tensile synthetic yarn braided/spiral metal) and outer layer (NR/SBR synthetic rubber, black or green and yellow in colors etc,).It is suitable for transportation of gasoline, kerosene, diesel, engine oil, lubrication oil or other mineral oil in industrial and mining machinery, oil depots, terminals at normal temperatures.

The petroleum industry plays an important part in the global economy and is a major export product for our domestic economy. Hydrocarbons and petrochemicals can be converted into a host of products we see and use on a daily basis. These include: plastics, rubber, textiles/materials, fertilizers, paints, detergents, solvents, fuels and many other products. New-Line carries a wide range of hose and fittings for critical in-plant, tank truck, ship-to-shore, refining, pipeline, or processing applications in the petrochemical industry. No matter what type of chemicals or temperatures you encounter, we have a solution to convey your products. When working with hazardous substances it is critical to specify brand name products with safe, solid performance records. We can properly test and certify hose assemblies before being put into service and at regular intervals thereafter.

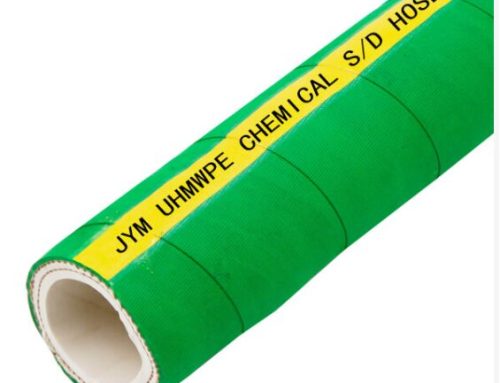

WHY YOU SHOULD BUY RUBBER OIL HOSE FROM JYM

JYM offers several brands of petroleum transfer hoses, braided oil hoses and oil delivery hoses based on user preferences. Inexpensive drop hoses typically will have less desirable handling characteristics, particularly at low temperatures, and may not be made of higher grade compounds for multi-year use. Our higher end hoses are indeed more expensive, but provide a viable option in rugged applications or where longer term durability is preferred. These are critical application hoses which should be inspected, tested, and certified in regular intervals.

JYM also offer on-site service solutions such as standardizing or color coding plant applications so users can be assured they are using the right hose for the right application. We can also provide many safety tips with regards to hose and fittings as well as preventative maintenance ideas to help ensure your facility and the environment remains safe and secure—contact us if you have any questions to help in product selection.