You may see all kinds of industrial rubber hose in our life. Discharge hose must be one of the most important to be used in various industries such as construction, marine, mining, industrial, municipal, and agriculture and come in sizes from 1.5 to 10 inch diameters. Most discharge hoses are made to handle water and mild chemicals. All discharge hoses are available in bulk or custom assembled to customer specifications.

When choosing a type of discharge hose, you should consider more than just the price point. So when asking what’s best for my application, consider that the most common options in hose (listed from lowest cost to highest) are lay flat, rubber, reinforced rubber and wire reinforced vinyl. These options, as with many things, hold true to the old saying, “you get what you pay for”.

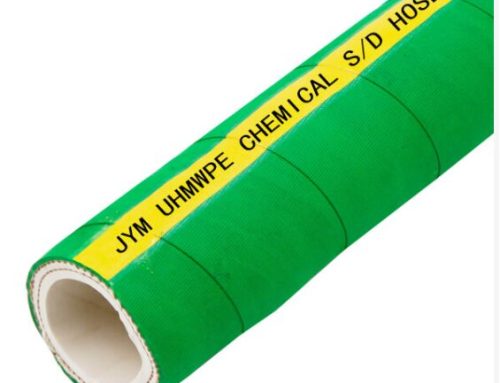

Discharge hose can be made of various material, comes in a variety of sizes, and is used to transport various liquids. Totally it can be divided into fuel oil delivery hose, discharge water hose, petroleum hose and multi-purpose discharge hose.

Our most popular hoses for general water removal are the lay-flat style discharge hoses, available in standard-duty (blue) and medium-duty (brown). Both are designed for “open end” water discharge, but have distinct application differences. Standard-duty blue lay-flat hose should only be used to discharge water over horizontal or declining grade, because it has a very low PSI rating (30-80* PSI). As grade increases so does pump head pressure, requiring a higher rated hose like the medium-duty brown lay-flat, which has a 150* PSI rating on all sizes through 6″ ID. In discharge applications that have a lot of trash and solids, you should consider our rubber water discharge hose, which has wear resistant EPDM tube and many times greater service life.

Let’s see the oil industry. The development of offshore and shallow sea oil fields, therefore, in addition to the use of drilling tubing and vibrating tubing, the petroleum industry also requires the use of shallow sea oil pipelines. Shallow sea submarine oil pipelines have been produced domestically, but floating or semi-floating oil pipelines and deep sea submarine oil pipelines still rely on imports. With the implementation of China’s offshore oil development strategy, the requirements for oil pipeline performance in offshore oil exploration will continue to increase.

Discharge hose can be made of various material, comes in a variety of sizes, and is used to transport various liquids.

Whether for suctioning or for discharge, the type of hose you choose depends on flexibility needs, durability needs, and price. When it comes to flexibility, lay flat hose may be your best choice. At JYM, we offer a wide range of durable discharge hose designed for us in irrigation, wash-down, fuel oil industry, cable covers and more. We carries discharge hoses for applications that require low, medium, or high working pressure. Choosing the wrong type discharge hose for the application can adversely impact pump output and lead to an inefficient system. Things to consider when choosing a discharge hose. So when choosing between the reinforced rubber and wire reinforced vinyl, you should think about things like flexibility and weight. The vinyl product is almost always lighter with a better bend radius, but can also be a bit pricier than the reinforced rubber. The rubber on the other hand typically is more abrasion and puncture resistant.

Specifically, the lower cost lay flat and non-reinforced rubber hose create additional head pressure as the pumps must work against the actual head and also work to keep the discharge hose expanded while both starting and pumping. While not good for all jobs, this type of hose can be effective for lower head, short horizontal run-out applications, where there is not a lot of total head to overcome. The other thing to consider when thinking about lay flat hose is the question of durability. It is easily the most sensitive when it comes to abrasion and puncture, and in severe conditions, lay flat can quickly turn in to a sprinkler hose. Non-reinforced rubber is much more durable than lay flat. However, with any non-reinforced hose, kinking and the resulting discharge line obstruction can often occur.

As I am sure you figured out by now, either type of reinforced hose will eliminate the false head created by the collapsing hoses and as a result the impact on system performance will be minimized. To sum up, the same discharge hose is not right for every job. Consider all of the job conditions and choose the hose which create the best mix of optimal system performance, durability and cost minimization.

Our JYM customer service staff is more than happy to help customers determine the best hose for their needs. Please Contact us by email at sales@goflexrubber.com for more information.